Get a Preferential Quotation

contact:

+86 139 2623 5878

The automatic molding machine dialogue interface can adjust and set various technical parameters of the machine on the computer screen within the defined scope of use.

The molding line adopts electromechanical integration technology such as microcomputer control and imported hydraulic, pneumatic and electrical components to improve the speed, accuracy, and reliability of the main engine. Automated and stable operation of the process and animation monitoring, fault finding and alarm functions of dynamic input/output. The remote control is possible.

Compared with similar molding lines, it has complete set functions, standardization level and maintainability in automation control, mechatronics level, equipment operation reliability, component wear resistance, simultaneous synchronous conveying, mechanical lower core, synchronous cooling, automatic sanding, etc. There are significant advances and advantages in performance.

High productivity, high precision of casting dimensions, low noise, low labor intensity, simple thick line, less auxiliary machine, small floor space, low investment in technology and construction, and energy saving. It is the most advanced and efficient tidal sand molding line.

The main operating features of the fully automatic horizontal boxless molding machine:

1. fully automatic one-button operation, no professional workers

Each time you complete the shape, you only need to press the start button once (not under the core working condition). If the workpiece is to be lowered, the program will automatically stop after the program is selected. After the core is finished, press the mold clamping button and the program will be completed automatically.

2. horizontal classification, convenient for the core.

3. Independent intellectual property rights and careful selection of quality components.

4. template installation: four screws fixed, replaced within five minutes, to adapt to frequent mold changes.

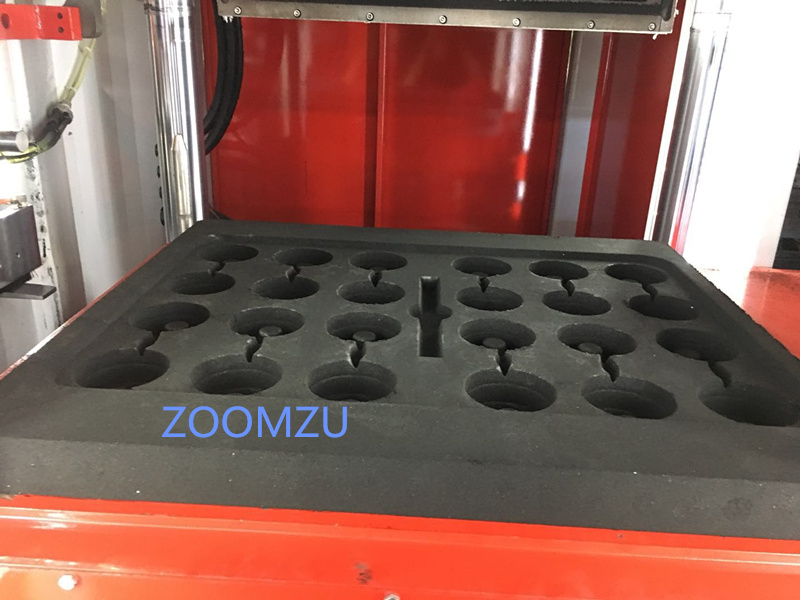

5. Mold hardness: The hardness of the mold can be adjusted freely according to the requirements of different castings. It is very convenient and quick to adjust several parameters, and the maximum can reach 85-90 degrees.

6. The height of the mold can be adjusted, and the sand can be saved: the upper and lower compacting plates can be adjusted to produce different mold heights.

7. Accuracy: The styling and merging are carried out in a unified positioning template and sandbox system with high repeatability.

8. The mold quality is constant and uniform: the machine adopts high-precision mechanical positioning system, microcomputer, and position detection linkage. The whole modeling process is fully automatic control, without human interference, so the modeling quality is stable, uniform, efficient and reliable.

9. with security protection: advanced light curtain protection to ensure the operator's personal safety

10. modeling speed: about 40-50 seconds per box.

11. mold size: 450X350mm, 550X450mm, etc., can be customized according to customers.

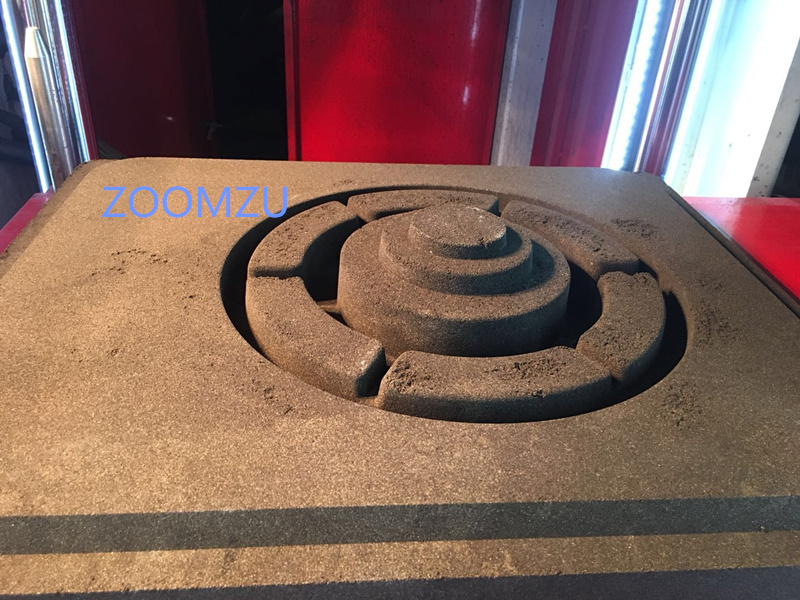

12. The material requirements for making the core are laminating sand or resin sand. The molding sand used for modeling is not high, it is ordinary sand, and the original sand can be used.