Guangdong Zoomzu Machinery Equipment Co., Ltd.is a manufacturer of automated molding machine and automated molding production line. As we know that manual molding is the molding worker using casting tools for sand mold manufacturing. There are many manual casting methods. The common molding methods include two parts molding, split-mold molding, sand molding, block molding, and three parts molding. However, manual casting has low production efficiency and high labor cost, and the foundry workers in the 1960s and 1970s have been slowly working, but the young people after 1980s and 1990s are not working because of the harsh environment and dust. At present, Guangdong Zoomzu Machinery Equipment Co., Ltd. has developed and produced the third generation of new automated molding machine by drawing on foreign advanced casting and casting technology. Zoomzu automated molding machine completely solves the problems of low production efficiency, high labor cost, large floor space, high production cost and difficulty in recruiting people.

Zoomzu automated molding machine is mainly used in the manufacture of mechanical parts, auto parts, hardware products, water meter cases, construction parts, valves, hydraulic parts, machine tool parts, fitness equipment, power equipment, cookers, motor parts, railway equipment, and other industries castings. It completely solves the problems of low production efficiency, high labor cost, large floor space, and high production cost. Characteristics of Zoomzu automated molding machine: high configuration, high efficiency, high survival rate, long service life, low failure, low energy consumption, and low maintenance cost.

Advantages of Zoomzu automated molding machine:

1. Fully automatic and one-button operation, no need for professional workers. The automated molding machine requires only one person to be on duty. The machine can be operated by ordinary workers after simple training. Greatly reduce labor costs and reduce production costs.

2. The horizontal parting and original sand shooting technology are adapted to facilitate the work of the lower core. The industry's first suspension sanding technology ensures that the sand is added to where it is needed, completely eliminating the shadow of sand.

3. The hardness of the mold is adjustable and the mold is easy to install. With a two-sided moldboard, it takes only 5 minutes to replace it. The precision of the combination is high. The sand compaction is above 85-90 degrees, and the mold quality is constant.

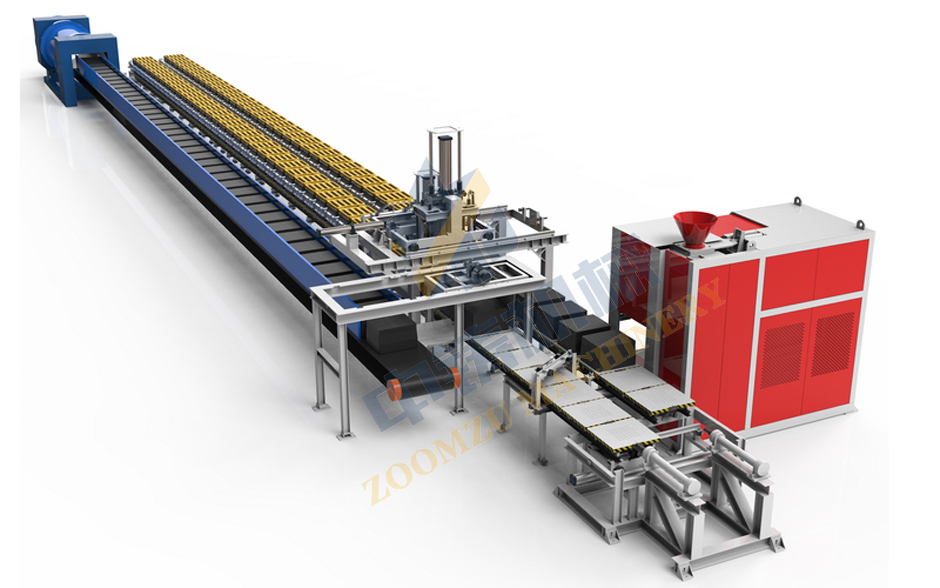

4. Not only can the automated production line be set up, but also can be used in a single machine. It can be equipped with conveyor lines to form a fully automated molding production line. The investment is small, the efficiency is high, the labor is saved and the land occupation is small.