The features of Zoomzu automatic horizontal molding machine:

1. Automatic one-button operation, simple and convenient

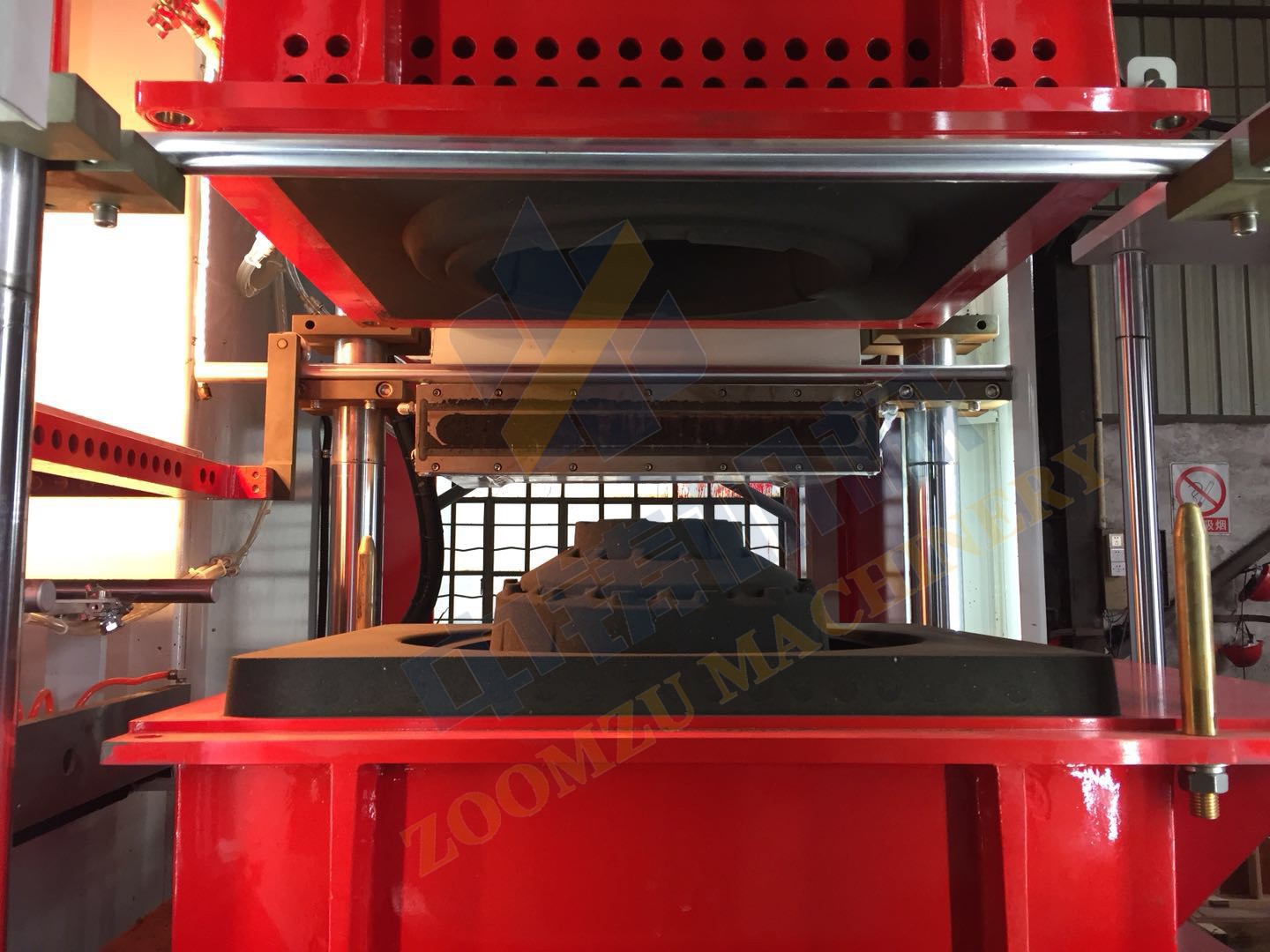

2. The machine is equipped with protective devices to ensure the personal safety of operators.

3. The sand shooting is in the horizontal direction, so it has filling performance, and the combination of the guide rectifying device installed in the sand blasting port and the sand blasting device is combined to completely improve the possible shadow defects. Horizontal casting, the process is more traditional, and the adaptability is wider.

4. Use vibration mode in the sandbox to make the sand filling in the sandbox more uniform

5. The sandbox is used for molding. After the molding is completed, the sandbox is closed and taken out, and the production efficiency is obviously improved.

6. Ensure the clamping and drafting accuracy of the upper and lower sandbox through the high-strength guides mounted on the frame and the four positioning rods on the upper and lower sandbox. Therefore, to ensure that the mold does not drop sand, mold clamping without error

7. Casting height and compaction ratio are optional. Users can flexibly choose different casting heights and compaction specific pressures according to the different castings so that the reasonable use of sand molds and the appropriate hardness of casting molds

8. The pattern is banned with 8 screws, easy to replace and save time

9. Adopt automatic lubrication system to avoid long-term non-lubrication and reduce the service life of the equipment

10. When a fault occurs, the screen will display the fault number, location, and content, which is convenient for the user to find the fault and take measures.