The sand casting process is a casting method in which sand has been used as the main molding material to prepare a mold. Sand casting is the most traditional casting method. Due to the characteristics of sand casting (not limited by the shape, size, complexity and alloy type, short production cycle and low cost), sand casting is still the most widely used casting method in casting production, especially single piece or Small batch castings.

The basic process of the traditional sand casting process has the following steps: sand mixing, plate making, core making, molding, pouring, falling sand, grinding processing, inspection, and other steps.

1. Sand mixing stage. Prepare sand and core sand for molding purposes. Generally, use a sand mixer to put the green sand and the right amount of clay to stir.

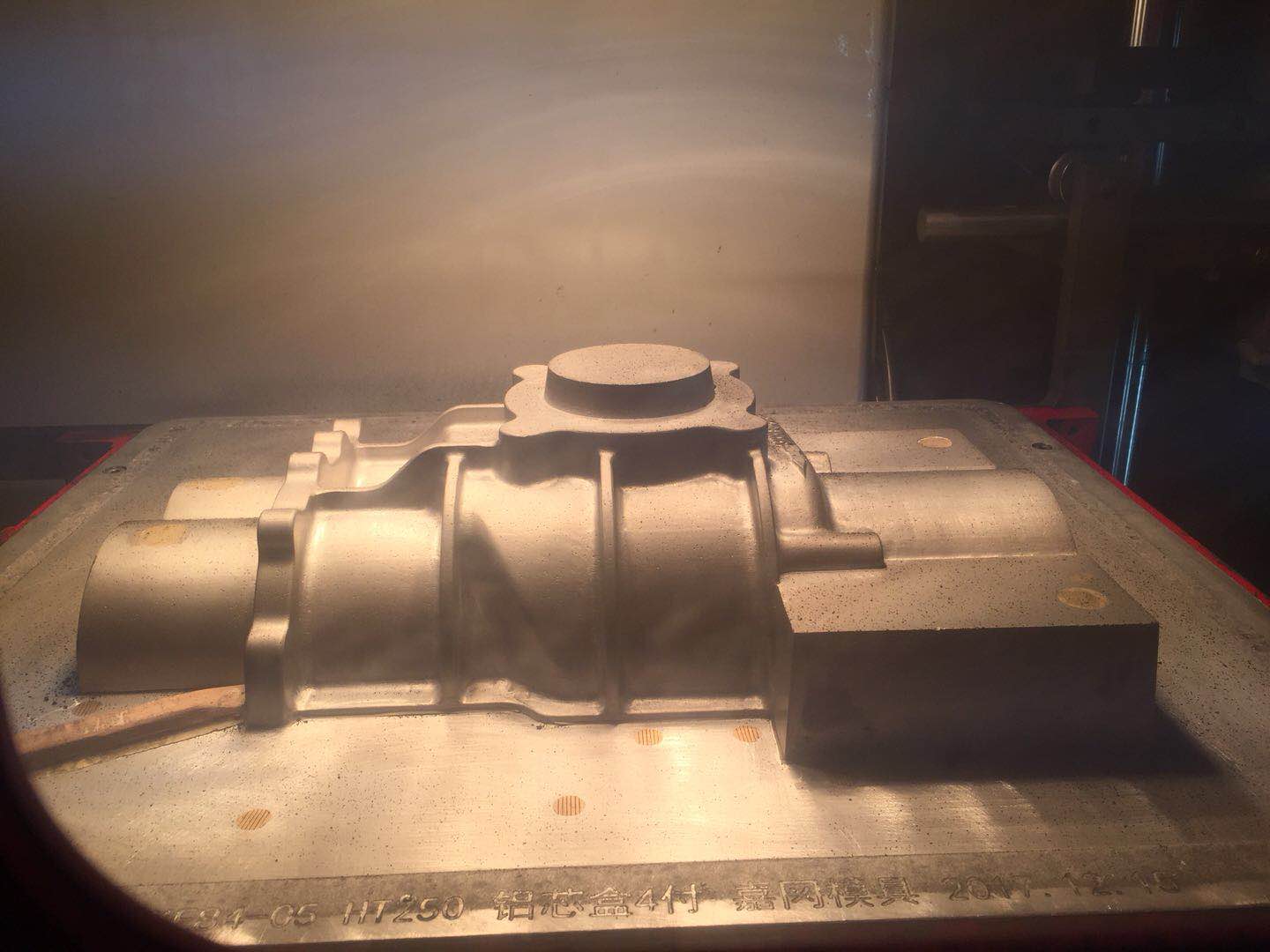

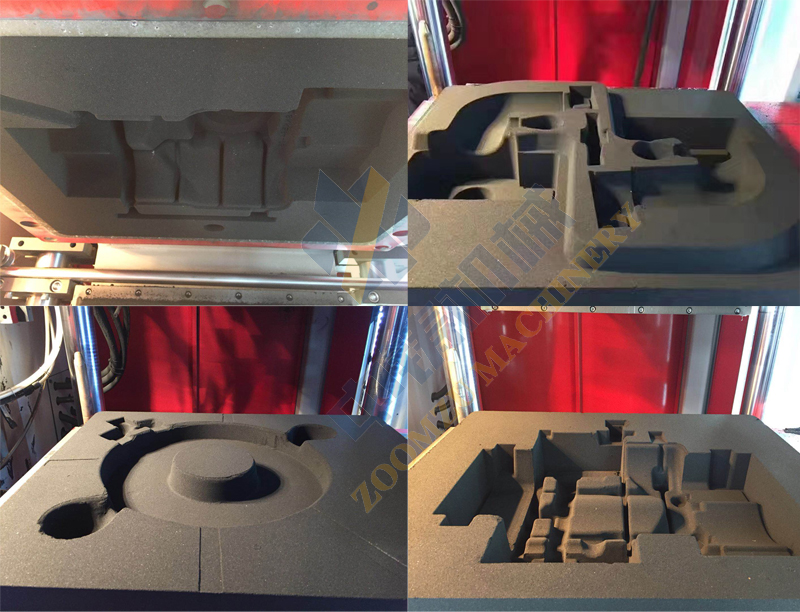

2. Plate making stage. According to the parts drawing, the mold and the core box can be made. Generally, the single piece can be made of wood plate and mass production castings can be made of the plastic plate or metal plate (commonly known as an iron plate or steel plate), and large-scale casting can be used for making the mold. Nowadays, the plates are basically made of engraving machines, so the production cycle is greatly shortened, and the plate making generally takes 2 to 10 days.

3. Molding (core making) stage. It includes molding (cavity with molding sand stroke casting), core making (forming the internal shape of the casting), and matching the mold (putting the core into the cavity and fitting the upper and lower flasks). Molding is a key link in casting. Using casting molding machine will greatly improve production efficiency.

4. The smelting stage. According to the required metal composition, the chemical composition is distributed, and the appropriate melting furnace is used to melt the alloy material to form a qualified liquid metal liquid (including qualified components and acceptable temperature). Smelting generally uses cupola or electric furnace (due to environmental protection requirements, the cupola is now banned, basically using electric furnace).

5. The pouring stage. Use a ladle to inject molten iron from the electric furnace into the finished mold. The pouring of molten iron requires attention to the speed of pouring so that molten iron fills the entire cavity. In addition, pouring molten iron is dangerous and requires safety.

6. The cleanup stage. After the casting, after the molten metal solidifies, take the hammer to remove the gate and shake off the sand of the casting, and then use a sand blasting machine to spray sand, so that the surface of the casting will appear very clean. The casting blanks that are not strictly required can be left after inspection.

7. Casting processing stage. For some castings with special requirements or some castings that cannot meet the requirements, simple processing may be required. Generally, the grinding wheel or the sander is used for processing and polishing, and the burrs are removed to make the castings smoother.

8. Casting inspection stage. Casting inspections are generally in the process of cleaning or processing, and unqualified ones have generally been found out. However, some castings have individual requirements and need to be checked again. For example, some castings require a central hole to be inserted into a 5 cm shaft, so you need to wear a 5 cm shaft to try.

After the above eight steps, the casting is basically formed.

Guangdong Zoomzu Machinery Equipment Co., Ltd. is a professional manufacturer of fully automatic horizontal parting flaskless sand casting molding machine. It integrates development, design, manufacture, and service.

The characteristics of Zoomzu casting molding machine: high configuration, high efficiency, high survival rate, long service life, low failure, low energy consumption, low maintenance cost; use of annealing process to improve the durability of the casting molding machine; more than 20 independent innovation patents; Control system: fully automatic operation of the machine, saving labor; easy to learn and operate. In order to meet the demands of users, we constantly innovate and improve the application technology and operating system of the casting molding machine to improve the stability and efficiency of the molding machine. Our factory can customize the model according to the size of the customer's product, and provide many-to-one service, and strive for excellence.